Back to top

Inspection Facility

We have maintained a cutting-edge inspection facility, which is equipped with all conventional equipment to ensure smooth incoming and outgoing of quality products. Utilizing our expertise, we design and develop functional gauges that ease out the inspection process. We focus on self periodic calibration of tools/ instruments. For testing purpose, we make use of precision instruments of Mitutoyo make.

Clientele

Why Choose Us?

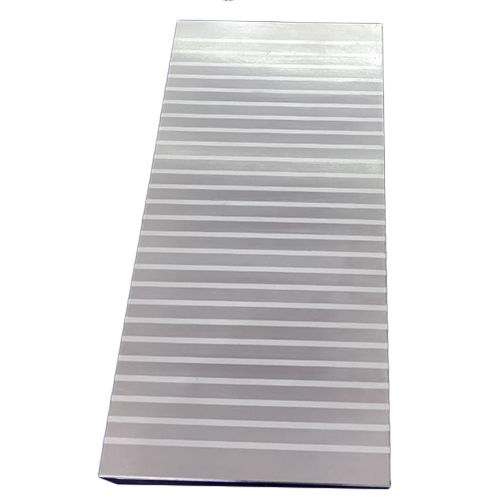

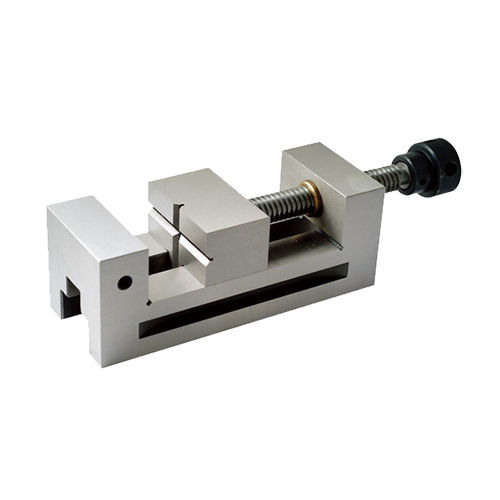

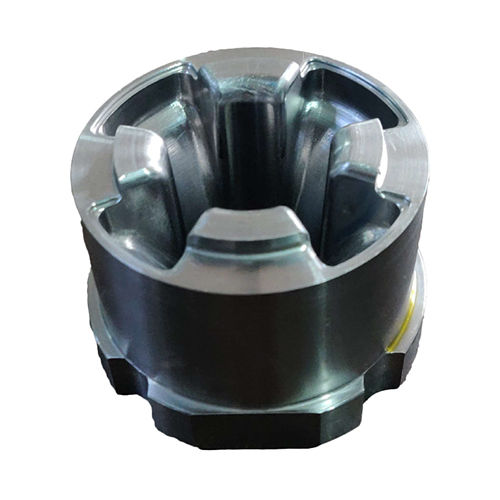

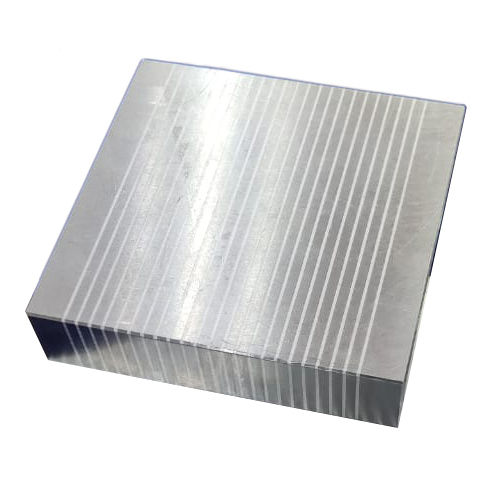

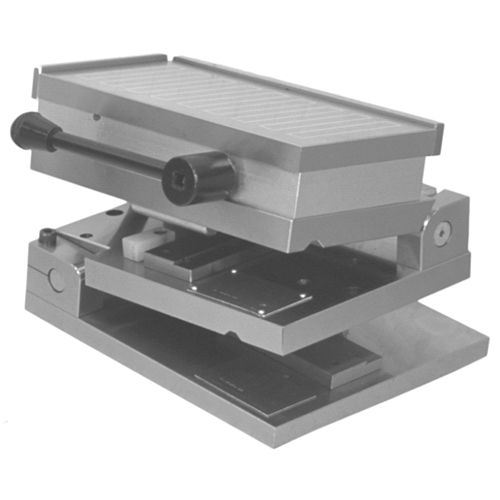

An experienced company, preferred for manufacturing and providing durable Electric Chamfering Machine, High Grade Magnet Transfer Block, Radius And Angle Dresser, Precision Grinding Vice, Axis Zero Setter, Eccentric Edge Finder, Touch Probe Sensor, and more.

In 1995, we, Rajshree Precision Pvt. Ltd., were formed in Faridabad, which is the largest industrial hub of the North India. A team of young and energetic engineers (TRTC=> An Indo-Danish Project) formed our company.

For more than past 29 years, as a manufacturer, we have been designing, manufacturing, and delivering a range of tool room spares, die spare parts and standard accessories. We follow systematic and organized work approaches and procedures to ensure quality job works and attain complete satisfaction of customers.

We work with the aim to provide the best products and services to customers.

Specialization

We hold specialization in developing and supplying Electric Chamfering Machine, High Grade Magnet Transfer Block, Radius And Angle Dresser, Precision Grinding Vice, Axis Zero Setter, Eccentric Edge Finder, Touch Probe Sensor, and many other products to customers in various standard sizes and specifications, and as per drawings.

Quality Policy

Gaining complete satisfaction of customers is our priority. We strive to use modern tools, and eliminate rework and wastages to develop and deliver high quality range to customers.

Infrastructure

In order to efficiently complete trade tasks and smoothly deliver products, we have maintained a sound infrastructure and equipped it with modern machines, tools and facilities. We have below machines in our setup:

For more than past 29 years, as a manufacturer, we have been designing, manufacturing, and delivering a range of tool room spares, die spare parts and standard accessories. We follow systematic and organized work approaches and procedures to ensure quality job works and attain complete satisfaction of customers.

We work with the aim to provide the best products and services to customers.

Specialization

We hold specialization in developing and supplying Electric Chamfering Machine, High Grade Magnet Transfer Block, Radius And Angle Dresser, Precision Grinding Vice, Axis Zero Setter, Eccentric Edge Finder, Touch Probe Sensor, and many other products to customers in various standard sizes and specifications, and as per drawings.

Quality Policy

Gaining complete satisfaction of customers is our priority. We strive to use modern tools, and eliminate rework and wastages to develop and deliver high quality range to customers.

Infrastructure

In order to efficiently complete trade tasks and smoothly deliver products, we have maintained a sound infrastructure and equipped it with modern machines, tools and facilities. We have below machines in our setup:

|

|

|

Inspection Facility

We have maintained a cutting-edge inspection facility, which is equipped with all conventional equipment to ensure smooth incoming and outgoing of quality products. Utilizing our expertise, we design and develop functional gauges that ease out the inspection process. We focus on self periodic calibration of tools/ instruments. For testing purpose, we make use of precision instruments of Mitutoyo make.

Clientele

|

|

Why Choose Us?

- We provide products after conducting 100% quality inspections to ensure that they are as per requirements or drawings provided by the clients.

- We make use of high quality imported raw materials for making products.

- We use special imported grades to develop products.

- We ensure that proper hardness is maintained in our products so that they can meet the requirements.

- We provide products with material test certificate and inspection reports.

- We have maintained a system as per which we do not need to take follow ups from customers to provide timely delivery of orders.

- We employ laser marking facility to have proper identification of products.

- We check that critical dimensions of products are maintained within the specified tolerance limit as low as 5 microns.

Send Inquiry

Send Inquiry Send SMS

Send SMS